Spaix is now available in the 2019 version with many new features and improvements. With this release, VSX – Vogel Software extends the software by additional functions such as the optional sizing of pumps with combustion engines, material-dependent correction of pump performance curves as well as improvements for food and beverage technologies.

“The development of the latest version of Spaix focused primarily on enhancing the user experience” says Managing Director Hanns-Henrik Vogel, commenting on the new presentation. “This includes the optimization of the program performance as well as a number of detail improvements of the entire application. Along with the new functions, additional modules round off the overall scope of Release 2019,” continues the manager.

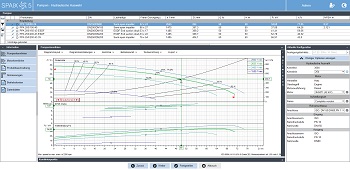

A focus among the additional modules is the new Spaix EngineSizer for the selection and configuration of pumps driven by a combustion engine. This extension is ideal for the design of aggregates where no electrical connection is available or must not be used for availability reasons. Possible applications range from construction site use to irrigation tasks in agriculture and fire protection systems. The new supplementary program is indispensable for pumps that are available with different motor variants. The program automatically determines the best drive according to the operating conditions specified by the user. Of course, all performance curve correction methods used in Spaix, such as for highly viscous fluids or impeller trimming, are available for these pumps as well. The speed range of the combustion engine is mapped directly in the pump performance curves in order to determine the actual operating point. The user can also specify a load profile to calculate the operating costs based on fuel consumption and the life cycle costs of the unit. Even a cost comparison between drive variants with electric motor and combustion engine is possible.

The Spaix PowerlossCalculator add-on has been extended to include material-dependent power and efficiency correction of pump performance curves. Pump manufacturers often use specific surface characteristics of the materials to optimize the pump hydraulics. With the new functionality, there is no need to duplicate the complete data by applying the correction functions to the existing pump performance curves. The resulting curves are displayed in the selection program immediately once the user has selected the appropriate material option for the pump.

With the improvements to the usability of the program, the integration of a progress indicator in the selection program is literally at the top of the list. This allows the user to see at a glance which selection step he is in and how many more steps will follow. This workflow is visualized by clear symbols in the header of the screen. Moreover, external applications can be linked via a button in the header. During the configuration process, a new permission setting may prevent certain users from changing configurations manually. In this case, the automatic configuration is “forced” by the program.

As part of the optionally available Spaix SpareSelector, the selection of part sets is now supported as independent articles.

The new Spaix InducerHandler will not only be interesting for food technology. The additional module enables the configuration-dependent switching of the NPSH curve when using an inducer. This provides a further possibility to modify the pump performance curves by the selected options. On the one hand, this avoids data redundancy and on the other hand offers the user an effective selection tool in which any changes to the equipment are immediately visualized. The addition of hectoliters (hl/s, hl/min, hl/h) to the units for the flow rate is likely to be another interesting aspect for companies in the beverage industry.

In the project management, users again have the possibility to send a project with all desired attachments directly from the program. This further simplifies the workflow during creation of quotations and saves valuable time by eliminating superfluous work steps. The same objective is pursued with the new function for assigning several price groups to one user. This allows registered users in the selection program to choose between different price groups, depending on the target group or market for which the respective quotations is to be created. For existing quotations or already selected products, the option of automatic price updates is also available.

When editing an inventory project, the data status can be compared with the current one and updated if required. In the Pump Comparison dialog, the operating cost comparison was integrated, offering the user a further criterion for the monetary and energetic evaluation of the selected pump models.

In the data maintenance program, the redesign of object access management can be highlighted. This is now done via a tree structure, which gives the user a better overview of the possible options and, thanks to the multiple selection, enables quick and uncomplicated editing of user (group) rights. In formula editing, the object selection has been enhanced with a search field, which simplifies the selection of individual objects considerably. Unnecessarily tied up disk space can be freed up thanks to the new data cleansing option. The program deletes data records that are not assigned to a pump (e.g. motor data records).

As part of the data sheet creation process, the quotation data sheet was extended to include columns with freely selectable fields for the integration of technical data, allowing the user to create an even more individual design. A new data sheet element is available for the area of pipe calculation, which enables separate output of the system curve.

In addition, there are a number of general customizations that make the use of the program more transparent and compliant with data protection regulations. For example, when updating Spaix 5, the user can see a list that summarizes all important program improvements. The Spaix Terms of Use are also now available via the main menu. An important aspect in the collection of personal data is compliance with the European data protection directives. Therefore, users of the statistics module of the web application can anonymize all usage data collected for the purpose of statistical analysis, in accordance with the DSGVO.

Spaix 5 Version 2019 is now available and will be made available to all maintenance customers free of charge within the next few days.

Picture: The Spaix 5 EngineSizer additional module optimizes pumps according to the speed range of the combustion engine drive. (Image: VSX – Vogel Software GmbH)