In an era striving to achieve sustainability at all costs, nanocellulose industry has emerged as a productive vertical of the polymers space, as the product is on the verge of evolving as the next-generation material. To be precise, nanocellulose has lately become highly popular across a slew of sectors, ranging from paper processing to coatings and power generation to food & beverage. This has created novel growth opportunities for research fellows and core companies working in material science technology. With nanocellulose products gaining popularity as alternatives over many other hazardous material, owing to its biodegradability and non-toxicity, nanocellulose market trends have undergone a dynamic transformation in recent times.

Having potentially identified the benefits of this super material, regulatory bodies have left no stone unturned in encouraging the adoption of nanocellulose products across the automotive and consumer electronics applications. One of the principal advantages of nanocellulose products is their recyclability, which can be sufficiently utilized in the consumer electronics sector. As per the U.S. Environment Protection Agency, more than 152 million smartphones are discarded annually, out of which only 10% are recycled. Taking into account the recyclability of nanocellulose products such as cellulose nanocrystalline and cellulose nano-fibrillated fiber, governments of various countries have been desperately encouraging manufacturers to adopt nanocellulose products for recycling smartphones and other electronic components. Initiatives such as the aforementioned to motivate manufacturers for using renewable alternatives are certain to transform nanocellulose market outlook over the years ahead.

Nanocellulose suppliers and manufacturers have lately been heavily investing in R&D activities to develop advanced nanocellulose products, considering how the material’s rigidity, strength, and transparency have aided its application in various domains. Lately, automakers have been shifting their focus toward the development of battery-based vehicles to reduce the dependency on fossil fuel-based vehicles that lead to pollutions. This has generated lucrative opportunities for battery manufacturers who have currently been conducting research programs for developing sustainable battery solutions. Invariably, these researchers have come to the conclusion that nanocellulose would be an ideal material to be used as electrodes in energy storages devices, thereby generating a new avenue of growth for nanocellulose suppliers.

Citing an instance of the aforesaid, in 2016, a team of Japanese researchers under Xudong Wang developed sustainable flooring with the use of nanofibers made from wood. These nanofibers have the ability to generate electricity, which can be connected to charge the batteries. As wood pulp is an easily available and low cost renewable waste product, power generation facilities assigning nanocellulose is likely to transform the future of technology trends in nanocellulose industry.

How paints and coatings applications have emerged to be a lucrative option for nanocellulose suppliers

The increasing awareness regarding the hazardous impact of conventional printing materials on the environment has significantly impacted nanocellulose industry share. In this regard, many core printing companies have been giving preference for cellulose nanocrystal (CNC) based sustainable coatings over synthetic coatings. In order to stay aligned with the factor of environmental safety, many of these companies have been using vegetable oil-based inks for printing on cellulose nanocrystal coated paper. Despite the fact that the drying time required for cellulose crystalline coatings surpasses the regular time frame, nanocellulose is being rapidly used in several printing technologies. This is certain to impel nanocellulose industry size from paints & coatings applications. In addition, the growing popularity of green printing solutions, which are mainly dependent on bio-based materials, will also soon replace synthetic coatings and additives in the manufacturing of paper and paperboard, further stimulating this vertical.

Taking into consideration the numerous environmentally friendly benefits of cellulose nanocrystals, many research organizations have been rapidly investing in the development of myriad nanocellulose product formulations. A few prominent topographies indeed, have come together to carry out collaborative research programs work for furthering the applications of nanocellulose products. For instance, U.S. and Israel have partnered to establish the Bidirectional Industrial Research and Development (BIRD) Foundation through which they look forward to encouraging researchers and companies for launching high-tech facilities. BIRD essentially promotes collaboration between myriad companies in the U.S. and Israel for conjoint product manufacturing.

Recently, the Israel Innovation Authority and the U.S. National Institute of Standards and Technology have approved a funding for eight new project, one among which is the ‘Melodea and ICL Performance Products’. The project basically is centered on the development of Cellulose Nanocrystal based formulations to come up with highly innovative, environmentally friendly industrial and architectural water-based coatings. Joint research programs such as the aforementioned between major countries is likely to impact nanocellulose industry share over the years ahead.

The deployment of green composites in the automotive sector to impel nanocellulose market size

Presently, nanocellulose products have emerged as one of the go-to material content in polymer composites. In fact, nanocrystals and cellulose nanofibrils are prominently used as reinforcing agents in thermoset and thermoplastic polymers. In a bid to comply with the regulatory frame of reference circulating around environmental safety, OEMs and automotive product suppliers have been preferring to use cellulose-based material on large scale as reinforcements in thermoplastic materials.

Speaking along similar lines, as nanocomposites possess the capability to reduce the carbon dioxide emissions during its production cycle and usage, regional governmental bodies have been encouraging automakers to rapidly adopt the product in the manufacturing process. The European Union (EU) for instance, as well as numerous other Asian governments are seemingly promoting the usage of nanocellulose products as composites in order to increase the recyclability of automotive components. The EU in fact, has implemented stringent regulatory norms to minimize wastage from scrapped vehicles, that have proved rather helpful for nanocellulose suppliers.

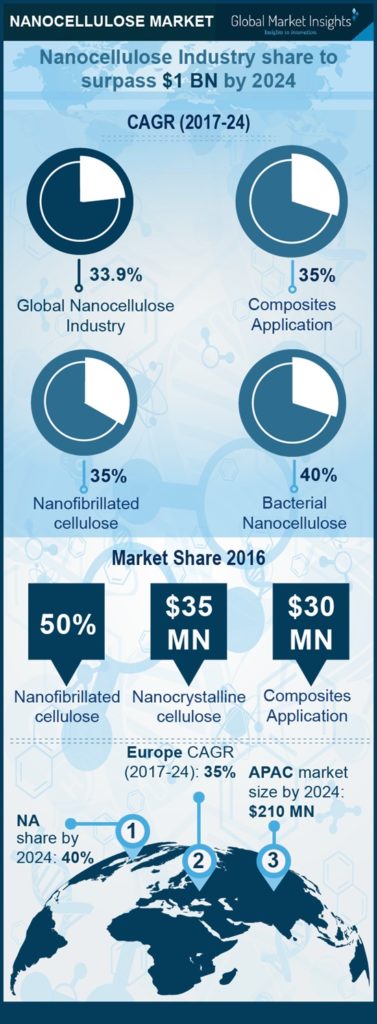

The increasing deployment of natural fiber composite materials in numerous automotive parts has led to a rise in fuel efficiency with lesser carbon dioxide emission. This is essentially because components manufactured from natural fiber can be manufactured quickly with less energy usage as compared to conventional materials, that tend to reduce the overall component costs. Pertaining to the same, prominent automakers including Ford, Daimler, Fiat, BMW, General Motors, Toyota, and Volkswagen are increasingly using cellulose-based products for improving the vehicle productivity and performance while simultaneously curbing carbon footprints. These automakers have also been giving preference to sisal, jute, flax, banana, wheat straw, wood, hemp, and coconut-based cellulose as reinforcements in plastic composites. With the help of these composites, several vehicle parts such as door trim panels, underbody panels, dashboard components, and interior components comprising speakers, toolbox area, seat cushions, and so on have been successfully manufactured. The increasing acceptance of natural composite materials across the automotive sector is thus slated to push nanocellulose market share from composite applications, slated to grow at an annual growth rate of 35% over 2017-2024.

The escalating use of nanocellulose products as composites is not prevalent solely across the automotive sector. Indeed, nanocellulose products have been finding substantial deployment in food packaging pertaining to their biodegradability and mechanical and chemical inertness. In the years ahead, nanocellulose products, aided by promising technological advancements and plausibly even their cost-effectiveness, will bring about a commendable transformation in nanocellulose industry trends. The growing awareness among the end-users and regulatory bodies about the significant benefits of nanocellulose products comprising nanocrystalline cellulose and nano fibrillated cellulose will play a pivotal role in generating growth opportunities for nanocellulose suppliers. That said, regional governments are now highly proactive with regards to promoting bio-economy, sustainability, and renewability trends, in the course of which verticals such as nanocellulose market will receive a lucrative boost. Driven by supportive regulatory initiatives and a highly noteworthy application landscape, nanocellulose industry size is anticipated to hit the coveted billion-dollar frontier by 2024.

Global Market Insights, Inc. has a report titled, “Nanocellulose Market Size By Product (Nanofibrillated Cellulose, Nanocrystalline Cellulose, Bacterial Nanocellulose), By Application (Composites, Paper Processing, Food & Beverages, Paints & Coatings, Oil & Gas, Personal Care), Industry Analysis Report, Regional Outlook (U.S., Canada, Germany, UK, France, Spain, Italy, China, India, Japan, Australia, Indonesia, Malaysia, Brazil, Mexico, South Africa, Saudi Arabia, UAE, Kuwait), Growth Potential, Price Trends, Competitive Market Share & Forecast, 2017 – 2024” available at

https://www.gminsights.com/industry-analysis/nanocellulose-market