The physical and digital worlds are accelerating fast, now colliding head-on. In manufacturing, this collision and resulting fusion represent the frontier of innovation and reinvention. Exemplifying this physical-digital collision is the use of “Augmented Reality” to design, manufacture, and service products. This blog discusses several exciting use cases for this technology in smart manufacturing.

AR Fuses the Physical and Digital Worlds

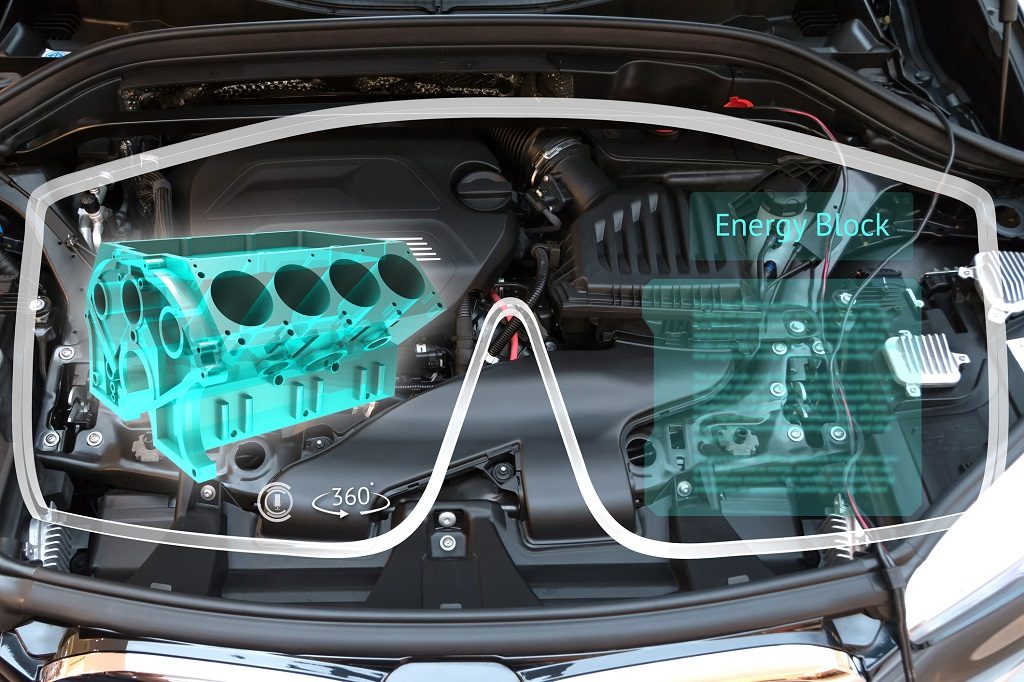

Augmented reality (AR) is the real-time use of information with real world objects. AR is a live direct or indirect view of a physical, real-world environment whose elements are supplemented by computer-generated sensory input such as video, images, graphics, sound, CAD, BIM, GPS, or other data. AR is a virtual reality (VR) technology. VR provides a computer-generated 3D environment that surrounds a user and responds to that individual’s actions in a natural way, through devices such as head-mounted displays, head tracking, and gloves providing haptic feedback.

Best-in-Class manufacturers have taken notice of AR, and are ahead in implementing the technology:

Figure 1: Augmented Reality Implementation

Source: Aberdeen Group, April 2017

While augmented reality is still growing and changing, the manufacturing and design industry have jumped in as key users. In manufacturing, AR is already making strides, driving operational efficiency by reducing production downtime, quickly identifying problems, and keeping processes moving.

Increasingly, the “model-based digital twin” powers AR. These digital twins live with the physical asset, providing a dynamic self-teaching model used to optimize its performance in conjunction with an Industrial Internet of Things (IIoT) platform. The model-based digital twin improves design, operations, and servicing via feedback loops between the physical world back to the virtual (digital) world. This combination of machine learning, coupled with physics-based modeling, enables organizations to see how their products performed in the past while simultaneously predicting the future.

Recommended for You

AR Use Cases Abound in Manufacturing

Digital Operations Visualization for Virtual Prototyping: Through virtual prototyping, product design engineers are able to study and test complex physics at a level of detail that was impossible to achieve through physical testing. AR provides an operational visualization of the device under design, improving the efficiency and usefulness of virtual prototyping.

Device Design Improvement: We have everything we need today to change the physical world via AR. Using AR and the model-based digital twin and IIoT, we can tweak a product design to match individual usage profiles of the actual device in the field. One example, of many, observed by Aberdeen Group at the recent LiveWorx 2017 show was a case study using an AR-based design tool to squeeze 30% more cooling capacity from a product.

Manufacturing Device Servicing via Mobile AR: Sophisticated yet easy-to-use AR authoring tools allow engineers to create entire “AR experiences” dedicated to showing technicians how to service various devices found on the factory floor. Using AR, a technician can quickly understand how to disassemble and proactively service or repair a faulty device in record time without prior experience with the particular device. This example shows how AR contributes to operational efficiency, as it all starts with operational uptime.

An example from LiveWorx 2017 illustrating this user case, was an AR experience application running on a mobile device (tablet). The application projected the virtual holographic device next to the identical physical device situated on the factory floor. On the tablet screen, the AR application then proceeded to disassemble the virtual device on the screen, providing clear instructions and understandable directions to the device technician.

AR-Enabled Building Information Model (BIM): Faced with a $60m wastewater plant redesign, Fairfax County, Virginia realized $4m in saving before the construction even began, and immersive AR was a key technology responsible for this savings.

First, the plant design team created a BIM based on a life-sized, 200-foot-by-100-foot 3D model of the future plant’s filter room. BIM is different from a 3D rendering in that it includes quantities: volume, area, square footage, and length. The team also developed a holographic model of the filter room.

Next, the team set up space for the 200-by-100-foot filter room inside a large public atrium and invited plant operators and engineers to conduct a walkthrough of the life-size, holographic, virtual AR model to evaluate the placement of pipes, pumps, valves, ductwork, and other components. In short order, walkthrough participants identified narrow walkways, inaccessible valves, and insufficient headroom. Based on their feedback, the filter room design was modified to meet their needs, which will save money on operations and maintenance.

Summary

We are still in the infancy of AR and VR. Today, both are probably at the same stage smartphones were in the early 2000s. In general, AR and VR have high potential to become the next generic human-machine interface. However, in manufacturing, the potential of this technology is even greater. Powered by the model-based digital twin and fed data via an IIoT platform, manufacturing engineers dream of the day when AR will enable them to manipulate a design on demand and make design changes on-the-fly. However, even at this early stage, abundant use cases of AR in manufacturing prove that this technology is well-positioned to make its mark, improving manufacturing in many ways for years to come.